Baikowski® alumina powders are designed for use in abrasive preparations for the maintenance of vehicles, specifically for the polishing of varnish, lacquer, and painted surfaces during automotive detailing, surface correction, and finishing operations. Our tailored grades, such as GE30, BA20, AD15, PB20CR, and PB50CR, offer optimal cutting efficiency, controlled deagglomeration behavior, and superior surface gloss for intermediate and superfinish polishing stages.

In automotive manufacturing, advanced polishing materials that deliver both precision and an impeccable finish are essential. At Baikowski®, we specialize in producing custom fine alumina powders that not only meet the highest standards but also provide a competitive edge by reducing polishing time and achieving a superior high-gloss finish. This is crucial in the intermediate and superfinish polishing stages, where balancing cutting efficiency with an outstanding gloss and transparency is key.

In automotive manufacturing, advanced polishing materials that deliver both precision and an impeccable finish are essential. At Baikowski®, we specialize in producing custom fine alumina powders that not only meet the highest standards but also provide a competitive edge by reducing polishing time and achieving a superior high-gloss finish. This is crucial in the intermediate and superfinish polishing stages, where balancing cutting efficiency with an outstanding gloss and transparency is key.

Intermediate Polishing: Accelerating the Polishing Process to Perfection

The intermediate polishing stage focuses on efficiently removing imperfections such as swirl marks, fine scratches, and oxidation. Baikowski® alumina powders are engineered to eliminate these defects quickly while minimizing surface abrasion, reducing polishing time and ensuring a smooth transition to the superfinish stage.

Superfinish: Achieving a Mirror-Like Shine Without Micro-Scratches

At the superfinish stage, the goal is to achieve a deep, reflective gloss that enhances the quality of the vehicle’s paintwork. Baikowski® alumina powders, with their controlled SSA and morphology, provide the fine abrasiveness needed to attain this result without introducing new imperfections.

Baikowski®’s Tailored Car Polish Solutions

Our fine alumina powders are engineered with a strict focus on quality and performance. The following properties are meticulously controlled to ensure optimal results in intermediate and superfinish polishing:

- Specific Surface Area (SSA): Our powders are formulated with optimized SSA values to achieve the right balance between cutting action and surface gloss. A lower SSA promotes aggressive cutting, while a higher SSA indicates finer particles essential for the superfinish stage, where a smooth, reflective surface is required.

- Morphology: We tailor the particle shape to optimize polishing efficiency. Sharp particles enhance cutting ability, while more rounded particles reduce the risk of micro-scratches, ensuring a flawless, high-gloss finish.

- Crystallinity: Our alumina powders feature the ideal crystallinity for consistent cutting performance. This ensures long-lasting effectiveness throughout the polishing process, reducing time spent while maintaining a high-quality finish.

- Particle Size Distribution (PSD): Controlling the PSD ensures consistent particle behavior throughout the process to prevent surface damage and achieve a good balance between removing imperfections and preserving the underlying surface quality.

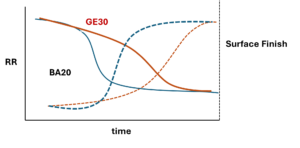

- Deagglomeration Ability: Our powders are designed to ensure alumina particles remain well-dispersed in the polishing slurry. Theses slurries consist of agglomerates of fine particles specifically engineered to break down during the polishing process. The controlled deagglomeration enables an initial strong cutting action that gradually transitions to a finer, softer polishing effect, leading to a mirror-like finish. This dynamic behavior contributes to both time-efficient processing and exceptional surface quality.

Choosing the right alumina powder with the optimal combination of SSA, morphology, crystallinity, PSD, and deagglomeration ability enables professionals to achieve the expected results.

Our proven products, such as GE30, GE15,BA20, PB20CR, and PB50CR, deliver unmatched performance in car polishing, shortening the process while achieving a brilliant finish. However, realizing their full potential requires the right combination of alumina solution and polishing pad. Ready-to-use products, such as GE15S slurry, are also available.

As demand for advanced varnish and lacquer polishing solutions continues to rise, Baikowski® remains a leader in the industry by providing custom alumina powders that meet the specific needs and process of our clients.

Illustration of the principle of GE30 & BA20 slurry polishing properties

RR (Removal Rate) / Surface finish over a period of time

| Standard product (Typical values) |

GE30 | BA20 |

|---|---|---|

| Crystalline phase | 80% α, 20% γ |

97% α, 3% γ |

| Specific Surface Area (m²/g) BET | 25 | 21 |

| PSD d50 (µm) Laser diffraction |

4.5 | 4.5 |

| Bulk Density (g/cm³) | 0.3 | 0.3 |

| Tapped Density (g/cm³) | 0.6 | 0.5 |

Additionally, we continue to develop new powders dedicated to varnish and lacquer applications, aimed at simplifying and accelerating the car polishing process.