High-Purity Alumina & Zirconia Medical Applications

4 and 5N alumina (HPA) and zirconia are pivotal in the field of bioceramics, offering a range of properties such as exceptional hardness and strength, non-cytotoxicity and biocompatibility.

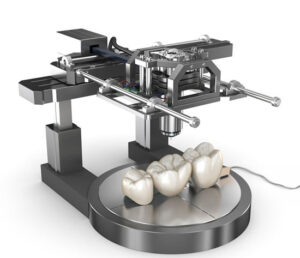

These materials are commonly used in high-stress environments such as artificial joints and dental implants due to their high wear resistance and low coefficient of friction.

Customization of bioceramic materials enables the enhancement of specific properties. For example, incorporating zirconia into the alumina matrix can significantly improve mechanical properties, resulting in a composite material that leverages the strengths of both substances. For this purpose, Baikowski® offers customized zirconia-toughened alumina (ZTA) composites, characterized by high chemical purity and homogeneous particle distribution, tailored to meet the precise needs of various applications.

Innovations in technology, such as ceramic 3D printing, are also expanding the possibilities, allowing for the creation of structures with complex geometries that can closely mimic natural bone or tissue structures.

Innovations in technology, such as ceramic 3D printing, are also expanding the possibilities, allowing for the creation of structures with complex geometries that can closely mimic natural bone or tissue structures.

This advancement is particularly significant in the development of scaffolds for tissue engineering, where the material’s properties can be precisely controlled to facilitate tissue growth and regeneration. In summary, the potential for innovation in bioceramics remains vast.

Bioceramic Properties

Depending on needs, High Purity Alumina (HPA)and zirconia exhibit a wide range of expected properties in bioceramics applications.

High Purity Alumina (Al₂O₃)

- Biocompatibility to allow contact with bodily tissues without causing adverse reactions. Combined with mechanical strength property in bone grafts as an example, it enables safe and effective bone regeneration.

- Wear resistance: A critical property in applications like hip joint replacements, where surfaces are subject to constant friction.

- Mechanical strength to ensure durability and longevity of the implants. Moreover, customization through advanced sintering and surface polishing provide optimal performance.

Zirconia (ZrO₂)

- High fracture toughness: Similar to alumina, zirconia is biocompatible but exhibits superior fracture toughness, reducing the risk of material failure under stress. Additionally, customizable surface treatments can help to improve osseointegration and long-term stability.

- Transformation toughening: This unique property allows zirconia to undergo phase transformation under stress, absorbing energy and enhancing toughness.

- Aesthetic appeal: its tooth-like color and translucency make zirconia ideal for dental applications. Mathym®, a Baikowski® group company, has developed zilight®, an aqueous colloidal nanosuspensions of yttria-doped zirconia nanoparticle that exhibits optical transparency while maintaining excellent mechanical properties.

Tailored Powders and Slurries for Your Specific Bioceramic Needs

Customization, including ready-to-use solutions can be achieved by Baikowski® teams to meet your specific bioceramic requirements such as :

- Grain size control: Fine-tuning grain size influences mechanical strength and wear resistance.

- Doping : To enhance properties like fracture toughness and wear resistance.

- Enhanced sintering behavior : The particle size and composition of the powder can be adjusted to optimize the microstructure and density of the materials, improving the mechanical properties.

- Porosity control: Porous structures promote bone ingrowth in orthopedic implants for instance.

By optimizing their properties and customizing them, HPA and zirconia can significantly enhance the performance and longevity of bioceramics. Contact us and we will design together the suitable product.