What is the purpose of ceramic nanofillers?

Nanofillers are nanoparticles of oxides embedded into a matrix of diverse materials (polymers, resins, metal…). The “classical” nanofillers are meant to lower the cost of a material by replacing a higher value material. Furthermore, ceramic nanofillers have the benefit of strengthen the physical properties of the matrix, namely its mechanical, optical or thermal properties.

Moreover, we’ll show here a new type of nanofillers, designed for high performance applications. We are talking about the agglomerate-free nanomaterial dispersions.

Properties of innovative ceramic nanofillers

The agglomerate-free nanomaterials dispersed in various media are bringing outstanding properties:

- High solid loading

- High transmittance

- Low viscosity.

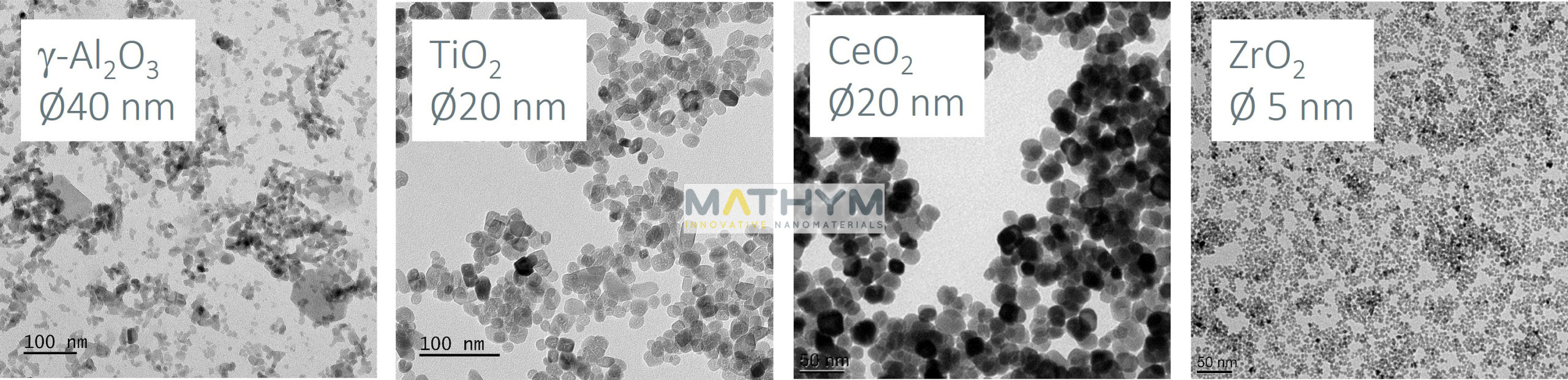

Mathym® and Baikowski® are producing several nanoparticles, which can be used as nanofillers. Here are some examples including high purity alumina (Al2O3) nano-dispersions, ceria (CeO2) and zirconia (ZrO2), as known as zilight® for Mathym:

The nanoparticles are agglomerate-free and delivered as a suspension. They are also known as nano-dispersions. Well dispersed, these nanoparticles used as nanofillers are solving some paradoxes:

- Radio-opacity / High transmittance, especially for the product YbF3 of Mathym, filyxio®

- Low sintering temperature / High density of the ceramic

- High refractive index / Low light scattering

Hence, the upper properties find their applications in several markets such as medical, technical ceramics, electronics, optronics…

Do you want to know more about our innovative ceramic nanofillers?