View battery related products

What are the components of the battery?

A lithium-ion cell appears as a sandwich comprising a positive electrode, a negative electrode (commonly called, respectively, cathode and anode) and a separator between the two electrodes.

The electrolyte is an organic liquid medium which allows the circulation of lithium ions between the poles.

What is the role of the separator inside the battery?

This electrolyte is held in a microporous membrane, the separator, which has a dual role.

On the one hand, the separator prevents the electrodes from coming into physical contact with each other, which would generate an internal short circuit.

On the other hand, it allows the transfer of lithium ions between the electrodes through the liquid electrolyte.

Technical challenges for the batteries

Batteries are facing technical challenges as they are more and more involved in our everyday life. For example in 2021, each French people had used on average 21 batteries or batterie-equipped devices a year.

Among the challenging parameters, safety is a “must-have” for obvious reasons. But it is far from being the only one.

In addition, the battery must show higher and higher energy density & power density (energy being packed for a given volume), be cost effective & durable (high cyclability). The end of life of a battery must also be considered: will it be reusable, what is its recyclability rate?

All those technical challenges are the main axes of innovation in the field.

Zoom on the separator

There are commercial polymer separators existing with sufficient mechanical and electrochemical stability and high porosity.

However, these polyolefin-type separators suffer from a poor electrolyte affinity due to their hydrophobicity. Moreover, they show low thermal structure integrity due to their low melting point. Eventually, it leads to an internal short circuit and a thermal runaway.

That is why new projects are emerging. For example, filling the polyolefin with thermally stable ceramic particles such as alumina (Al2O3 filler) shows a notorious reduction in thermal shrinkage.

Indeed, the ceramic coating is an alternative approach. It leads to « ceramic-coated separators » (CCSs) .

View battery separator related products

What do chemical oxides, like HPA, bring to the battery?

By coating a ceramic slurry composed of ceramic particles and binder onto a polyolefin base film, the thermal shrinkage of polyolefin can be drastically reduced.

Additionally, the hydrophilic surface property of ceramic particles and the high porosity of CCSs can provide electrolyte wettability and efficient lithium ions transport, respectively, which improves the electrochemical performance. Furthermore, not only the coating process is viable for mass production, but it is also the most effective way to make separators at low costs and are the most attractive candidate for the development of safety-enhanced separators.

The separator, loaded with Al2O3 particles or coated with an Al2O3 layer, can be likened to a porous network in which the continuous phase will be the electrolyte.

The Li+ ions will move within this porous network to reach the electrodes of the battery.

The set [Polymer separator – Al2O3 particles – pores] will condition all the desired properties for a separator.

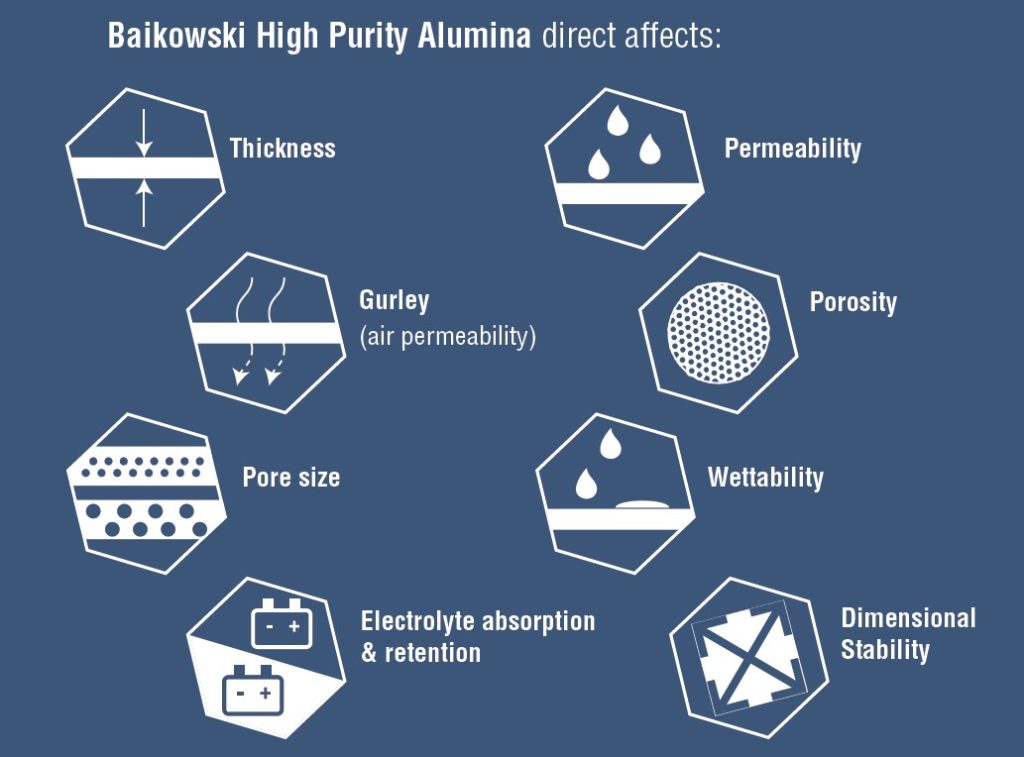

Thus, it is reasonable to assume that anything that changes the characteristics of the porous network will affect the properties and functionality of the separator.

Why using Baikowski products for battery projects?

We know that our oxides can influence the above parameters as well as the overall properties of the separator, including porosity, permeability, high temperature stability & strength. That’s why Baikowski has been developing high purity alumina with highly controlled properties:

- Particle size distribution

- Rate of fine particles

- Pore volume

- Pore distribution

- Zeta potential

- Chemical purity

Indeed, we are aware that some parameters of the powder can be decisive for its implementation into the customer’s process:

- Flowability of the powder

- Pulverulence

- Ability to disperse the powder in the continuous phase

- Viscosity for a given charge rate

- “Lifetime” of the mixture (evolution of the viscosity as a function of time)

Through our highly controlled products, we are willing to offer the best technical solution for the final separator. In the end of the day, our customer can control interesting characteristics for an optimal separator:

- Thickness of Al2O3 layer (or finished separator)

- Density of loaded separator compared to blank separator

- Electrolyte uptake

- Quality of the adhesion of the layer of alumina deposited (case of the coating)

We also provide HPA with high specific surface area, adapted to anode & cathode material coating.

There also are an interesting potential for the use of high purity alumina in emerging technology, such as the Solid-State Electrolyte, and more precisely the Solid Polymer Electrolyte (SPE).

Discover how HPA overcomes battery technology limitations, including solid state batteries?

Willing to go one step further into the research in the battery field, Baikowski is part of the BEPA since 2021. The Battery European Partnership Association regroups all the battery stakeholders from the European Research Community.