Ready-to-Use Solutions: Advanced Oxide Materials for Cutting-Edge Applications

The world of advanced materials relies heavily on oxides like High-Purity Alumina, spinel, ZTA. These materials offer exceptional properties such as strength, thermal stability, and chemical resistance, making them crucial for various applications. Working with oxides can involve complex processes like milling and dispersing, requiring specialized equipment and expertise.

Baikowski® offers ready-to-use and Ready-To-Press (RTP) solutions that simplify these complex operations. Our expertise in powder deagglomeration includes jet-milling, ball milling, and wet-milling techniques, facilitating the design of innovative and high performance materials. Our offerings also include:

· Slurries: Wet-milled suspensions with uniform particle size distribution and enhanced flowability.

· Slurries: Wet-milled suspensions with uniform particle size distribution and enhanced flowability.

· Spray-Dried Powders: Powders obtained via spray-drying of a slurry, providing excellent flowability and consistency for pressing applications. These can be binder-added or binder-free, depending on the desired properties.

· Freeze-dried solutions: Powders obtained via water removal through sublimation, offering long shelf life and precise control over particle size.

Benefits of our Ready-to-Use Solutions

Ready-to-use and RTP solutions offer numerous customer benefits, including:

· Convenience: Pre-processed solutions eliminate the need for in-house skills and equipment, saving time and resources.

· Convenience: Pre-processed solutions eliminate the need for in-house skills and equipment, saving time and resources.

· Consistent Product Quality: By offering superior performance and process compatibility, these solutions provide enhanced ceramic properties and consistent polishing results.

· Waste Reduction: They minimize waste by reducing errors and improving process efficiency.

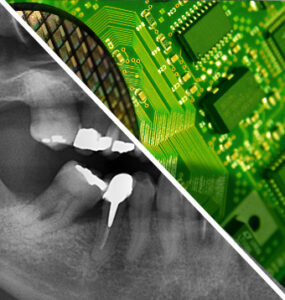

High-Tech Applications Across Various Industries

Our tailored ready-to-use and RTP solutions have revolutionized various markets, including energy, battery, healthcare, electronics, and 3D printing.

Our tailored ready-to-use and RTP solutions have revolutionized various markets, including energy, battery, healthcare, electronics, and 3D printing.

For instance, the enhanced flowability and controlled particle size of these ready-to-use solutions have positively impacted the injection molding, polishing, and additive manufacturing processes. They have supported the rapidly growing field of ceramic 3D printing by providing consistent powders and slurries, enabling the creation of detailed and durable components.

Baikowski® Custom Solutions

At Baikowski®, we are committed to supporting your innovative projects with custom slurries and powders tailored to your processes and applications.

Contact us to learn more about our offerings and to discuss your needs. Together, we can drive the future of material science and technology.