Ceramic Matrix Composites (CMCs) represent a transformative breakthrough in materials science, addressing the growing demand for high-performance materials in extreme environments. These composites retain the thermal stability, corrosion resistance, and mechanical strength of ceramics while overcoming their inherent brittleness through composite engineering.

CMCs are increasingly utilized in aerospace, energy, medicine, and electronics, where lightweight structures, high-temperature resistance, and mechanical durability are essential.

CMCs are increasingly utilized in aerospace, energy, medicine, and electronics, where lightweight structures, high-temperature resistance, and mechanical durability are essential.

To fully unlock their potential, precise control over the matrix composition is crucial. In fact, the matrix must ensure:

✔ Excellent dispersion of ceramic particles in the slurry

✔ High solid loading with low viscosity for better infiltration

✔ Compatibility with additives to tailor performance

✔ High reactivity for efficient consolidation

✔ Controlled porosity to enhance mechanical properties

1. Ox/Ox CMCs: Performance and Challenges

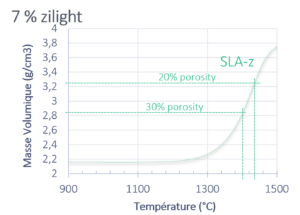

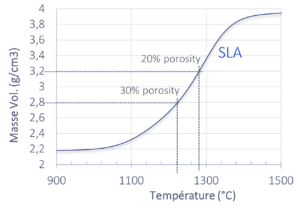

Ox/Ox CMCs are typically composed of alumina or mullite fibers embedded in an oxide matrix. These fibers enhance strength, toughness, and thermal resistance, while the matrix plays a key role in load transfer, fiber protection, and crack deflection. Studies show that an optimal matrix porosity of around 30% is ideal for balancing mechanical strength and thermal performance.

Several challenges must be addressed to achieve such Ox/Ox CMC performance, including:

✔ Mechanical Degradation of Ceramic Fibers at High Temperatures

✔ Grain Growth Leading to Reduced Mechanical Strength

✔ The Need for Low-Temperature Sintering to Preserve Fiber Integrity

However, achieving this requires precise control over particle size distribution, doping levels, and viscosity. This is where Baikowski®’s SLAz slurry comes into play, offering an advanced high-purity alumina and nano-zirconia solution that meets these critical parameters.

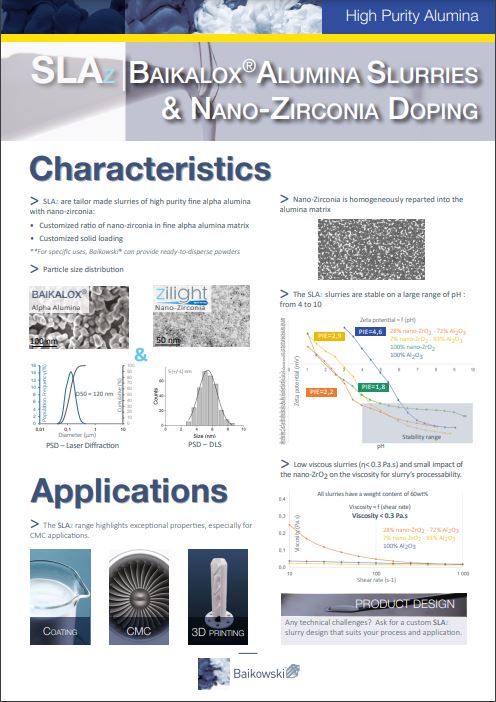

2. SLAz: The Key to Next-Generation Ceramic Matrix Composites

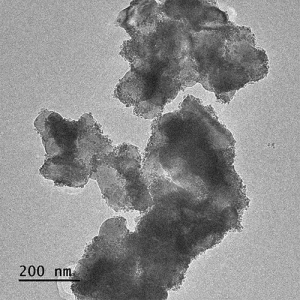

SLAz is Baikowski®’s high-purity α-alumina slurry, enhanced with a customized ratio of zilight® nano-zirconia—the smallest nano-zirconia on the market—developed by Mathym®, a Baikowski® Group company. The SLAz range includes a doping level of nano zirconia up to 28 wt%, a solid loading of slurries up to 60 wt%, low viscosity, and a large pH range, that enable:

1- Controlled Grain Growth & Microstructure Stability

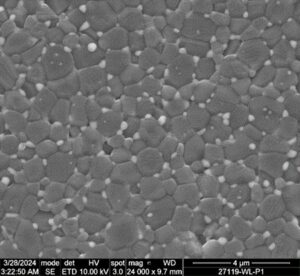

Mathym’s nano-zirconia effectively limits excessive alumina grain growth, helping to preserve the mechanical integrity of the matrix. Additionally, its uniform dispersion ensures consistent microstructural performance throughout the composite, leading to enhanced reliability and durability.

2- Enhanced Processability & Stability

SLAz remains stable across a wide pH range (4–10), ensuring long-term slurry stability during processing and optimizing manufacturability. SLAz‘s responsiveness to sintering allows it to consolidate at low temperatures, preserving fiber integrity.

3- Enhanced Fiber Protection & Mechanical Properties

SLAz could reinforces the alumina matrix, making it an ideal solution for high-performance applications in extreme environments.

3. SLAz Slurry Characterization

Baikowski® has rigorously engineered SLAz to meet high-performance standards such as:

✔ Low Viscosity – Ensures easy processing and fiber infiltration.

✔ Zeta Potential Optimization – Provides a stable suspension with a wide pH range.

✔ Controlled Doping Levels – Up to 28% nano-zirconia, ensuring fine microstructure control.

✔ Tailored Solid Loading – Up to 60 wt% for high-density matrix formation.

✔ Homogeneous Dispersion – Guarantees uniform properties after sintering.

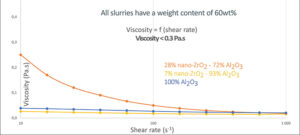

Viscosity

- Viscosity remains low (below 0.3 Pa.s)

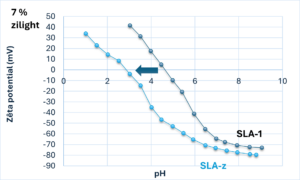

Zeta potential curves

Zeta potential curves of SLAz and pure zilight® dispersion are similar:

- High SSA

- Higher dispersant amount in zilight® dispersion

- zilight® tends to form a layer on alumina grain surface

3. Ceramics characterization SLAz

Densification occurs at higher temperature with zilight® doping and Homogeneous dispersion limits grain growth.

For more information on Baikowski’s CMC solutions, download our leaflet and do not hesitate to contact our team.

SLAz SLURRIES

for CMC applications

Download the SLAz leaflet

Download the SLAz leaflet

If Baikowski® continues to innovate for high-performance Ox/Ox CMC, our R&D team do not stop there.

Recognizing the growing demand for mullite-based CMCs, Baikowski® has also developed SLMz, a tailor-made mullite slurry doped with zilight® nano-zirconia.

Early results show promising effects similar to SLAz, including a comparable impact on zeta potential, an IEP downshift dependent on zilight® loading, and a significant decrease in viscosity.